I-Reflow soldering (i-reflow soldering / i-oven) yeyona ndlela isetyenziswa ngokubanzi kwi-solder yecandelo le-SMT kwishishini le-SMT, kunye nenye indlela yokudibanisa i-wave soldering (i-Wave soldering).I-Reflow soldering ifanelekile kumacandelo e-SMD, ngelixa i-wave soldering ifanelekile Kwi-pin electron components.Kwixesha elizayo ndiza kuthetha ngokuthe ngqo ngomahluko phakathi kwezi zimbini.

I-Soldering kwakhona

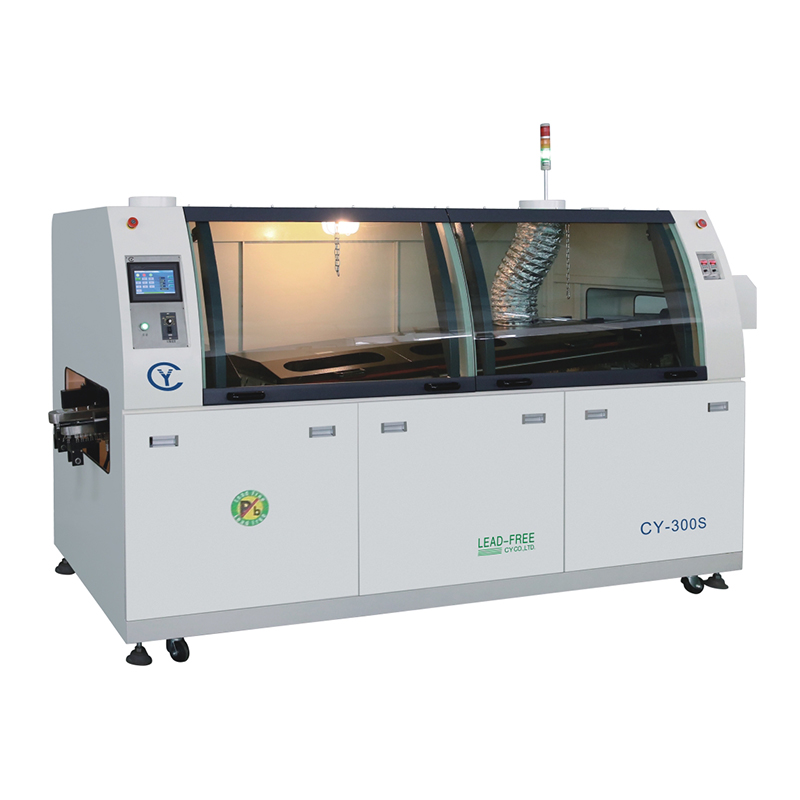

Wave Soldering

I-Reflow soldering nayo yinkqubo yokuphinda ithengise.Umgaqo wayo kukuprinta okanye ukufaka isixa esifanelekileyo sokuncamatheliswa kwe-solder (I-Solder paste) kwi-PCB pad kwaye unyuse amacandelo ahambelanayo okwenziwa kwetshiphu ye-SMT, kwaye emva koko usebenzise i-convection yomoya oshushu wokufudumeza we-oven yokufudumeza ukufudumeza intlama intlama iyanyibilika. kwaye yenziwe, kwaye ekugqibeleni i-joint solder ethembekileyo yenziwa ngokupholisa, kwaye icandelo liqhagamshelwe kwi-PCB pad, edlala indima yokudibanisa oomatshini kunye noqhagamshelwano lombane.Inkqubo ye-reflow soldering inzima kwaye ibandakanya uluhlu olubanzi lolwazi.Yeyobugcisa obutsha bezifundo ezahlukeneyo.Ngokuqhelekileyo, i-reflow soldering yahlulwe yangamanqanaba amane: ukushisa kwangaphambili, ubushushu obungaguqukiyo, ukugeleza kwakhona, kunye nokupholisa.

1. Indawo yokufudumala

Indawo yokufudumeza: Linqanaba lokuqala lokufudumala kwemveliso.Injongo yalo kukutshisa imveliso ngokukhawuleza kwiqondo lokushisa eliqhelekileyo kwaye isebenze i-solder paste flux.Kwakhona kukuphepha ubushushu becandelo obubangelwa kukufudumeza okukhawulezileyo kobushushu obuphezulu ngexesha lenqanaba elilandelayo lokucwiliswa kwetoti.Indlela yokufudumala efunekayo kumonakalo.Ngoko ke, izinga lokushisa libaluleke kakhulu kwimveliso, kwaye kufuneka ilawulwe ngaphakathi koluhlu olufanelekileyo.Ukuba ikhawuleza kakhulu, ukothuka kwe-thermal kuya kwenzeka, kwaye ibhodi ye-PCB kunye namacandelo aya kuba phantsi koxinzelelo lwe-thermal, ebangela umonakalo.Ngexesha elifanayo, i-solvent kwi-solder paste iya kunyuka ngokukhawuleza ngenxa yokufudumala ngokukhawuleza.Ukuba icotha kakhulu, i-solder paste solvent ayiyi kukwazi ukuguquguquka ngokupheleleyo, okuya kuchaphazela umgangatho we-soldering.

2. Ummandla wobushushu rhoqo

Ummandla weqondo lobushushu rhoqo: injongo yayo kukuzinzisa ubushushu becandelo ngalinye kwi-PCB nokufikelela kwimvumelwano kangangoko kunokwenzeka ukunciphisa umahluko wobushushu phakathi kwamacandelo.Kule nqanaba, ixesha lokufudumala kwecandelo ngalinye lide.Isizathu sesokuba amacandelo amancinci aya kufikelela kwi-equilibrium kuqala ngenxa yokunciphisa ubushushu obuncinci, kwaye amacandelo amakhulu aya kufuna ixesha elaneleyo lokubamba amacandelo amancinci ngenxa yokufunxa ubushushu obukhulu.Kwaye uqinisekise ukuba i-flux kwi-solder paste iguquguquke ngokupheleleyo.Kule nqanaba, phantsi kwesenzo se-flux, i-oxides kwiipads, iibhola ze-solder kunye nezikhonkwane zecandelo ziya kususwa.Kwangaxeshanye, i-flux iya kususa i-oyile kumphezulu wamacandelo kunye neepads, yandise indawo ye-soldering, kwaye ithintele amacandelo ukuba aphinde afakwe kwi-oxidized.Emva kokuba eli nqanaba liphelile, icandelo ngalinye kufuneka ligcinwe kwiqondo lokushisa elifanayo okanye elifanayo, ngaphandle koko kunokubakho i-solder engalunganga ngenxa yomahluko ogqithisileyo wokushisa.

Iqondo lobushushu kunye nexesha lobushushu obuqhubekayo buxhomekeke kubunzima boyilo lwePCB, umahluko kwiintlobo zecandelo kunye nenani lamacandelo, ngokuqhelekileyo phakathi kwe-120-170 ° C, ukuba i-PCB inzima kakhulu, iqondo lokushisa lommandla wokushisa rhoqo. kufuneka kugqitywe ngobushushu obuthambileyo be-rosin njengesalathiso, injongo kukunciphisa ixesha lokuthengisa kwindawo yokubuyela emva kokuphela, indawo yokushisa eqhubekayo yenkampani yethu ikhethwa ngokubanzi kwii-degrees ze-160.

3. Indawo yokuhanjiswa kwakhona

Injongo yommandla wokubuyisela kwakhona kukwenza i-solder paste ifikelele kwimo etyhidiweyo kwaye imanzise iipads kumphezulu wezinto eziza kuthengiswa.

Xa ibhodi PCB ingena kwindawo reflow, iqondo lobushushu liya kunyuka ngokukhawuleza ukwenza i-solder paste ifikelele kwimo yokunyibilika.I-melting point ye-lead solder paste Sn: 63 / Pb: 37 yi-183 ° C, kunye ne-lead-free solder paste Sn: 96.5 / Ag: 3 / Cu: Indawo yokunyibilika ye-0.5 yi-217 ° C.Kule ndawo, ubushushu obunikezelwa yi-heater bubuninzi, kwaye ukushisa kwesithando somlilo kuya kufakwa kwindawo ephezulu, ukwenzela ukuba ukushisa kwe-solder paste kuya kunyuka kwiqondo lokushisa eliphezulu ngokukhawuleza.

Iqondo lobushushu eliphakamileyo legophe le-reflow soldering ngokuqhelekileyo limiselwa yindawo yokunyibilika ye-solder paste, ibhodi yePCB, kunye nobushushu obuxhathisa ubushushu becandelo ngokwalo.Iqondo lokushisa eliphezulu lemveliso kwindawo yokubuyisela kwakhona iyahluka ngokohlobo lwe-solder paste esetyenzisiweyo.Xa sithetha ngokubanzi, akukho Elona qondo liphezulu lobushushu lokuncamathelisa ilothe kwi-solder lidla ngokuba yi-230-250°C, kwaye elo le-lead solder paste lidla ngokuba yi-210-230°C.Ukuba iqondo lobushushu lisezantsi kakhulu, kuya kuba lula ukubangela i-welding ebandayo kunye nokungamanzi ngokwaneleyo kwamalungu e-solder;ukuba iphezulu kakhulu, i-epoxy resin type substrates iya kuthi kwaye inxalenye yeplastiki ithanda ukuphekwa, i-PCB iphosa amagwebu kunye ne-delamination, kwaye iya kukhokelela ekwakhiweni kwee-eutectic zetsimbi ezigqithisileyo, okwenza ukuba amalungu e-solder abe brittle, enze buthathaka amandla okuwelda, kunye nokuchaphazela iimpawu zomatshini wemveliso.

Kufuneka kugxininiswe ukuba i-flux kwi-solder paste kwindawo yokubuyisela iluncedo ekukhuthazeni ukumanzisa kwe-solder paste kunye nokuphela kwe-solder yecandelo ngeli xesha, kunye nokunciphisa ukunyanzeliswa komphezulu we-solder paste.Nangona kunjalo, ngenxa ye-oksijini eshiyekileyo kunye ne-oxides yesinyithi engaphezulu kwisithando somlilo, ukukhuthazwa kwe-flux kusebenza njengesithintelo.

Ngokuqhelekileyo ijiko elilungileyo lobushushu bomlilo kufuneka lihlangabezane neqondo lobushushu lencopho nganye kwi-PCB ukuze lingqinelane kangangoko kunokwenzeka, kwaye umahluko kufuneka ungadluli kwiidigri ezili-10.Kuphela ngale ndlela sinokuqinisekisa ukuba zonke izenzo ze-soldering ziye zagqitywa ngempumelelo xa imveliso ingena kwindawo yokupholisa.

4. Indawo yokupholisa

Injongo yendawo yokupholisa kukupholisa ngokukhawuleza i-solder paste particles, kwaye ngokukhawuleza wenze i-solder ekhanyayo kunye ne-arc epholileyo kunye nomxholo ogcweleyo we-tin.Ngoko ke, iifektri ezininzi ziya kulawula ummandla wokupholisa, kuba ulungele ukubunjwa kwamalungu e-solder.Xa sithetha ngokubanzi, isantya sokupholisa esikhawuleza kakhulu siya kwenza intlama yesolder etyhidiweyo ifike kade kakhulu ukuba iphole kwaye ikhuseleke, okukhokelela ekuhleni, ekuloleni kunye nakwimibhobho edityanisiweyo yesolder edibeneyo.Izinga lokupholisa eliphantsi kakhulu liya kwenza umgangatho osisiseko we-PCB pad surface Izinto zixutywe kwi-solder paste, eyenza i-solder joints ibe rhabaxa, i-solder engenanto kunye ne-solder emnyama.Ngaphezu koko, zonke iimagazini zentsimbi kwiiphelo ze-soldering zamacandelo ziya kunyibilika kwiindawo zokuxilisa, ezibangela ukuba iziphelo ze-soldering zamacandelo zixhathise ukumanzisa okanye ukuthambisa kakubi.Ichaphazela umgangatho we-solder, ngoko ke izinga lokupholisa elilungileyo libaluleke kakhulu kwi-solder joint formation.Ngokuqhelekileyo, abanikezeli be-solder paste baya kucebisa ireyithi yokupholisa edibeneyo ye-solder engu-≥3°C/S.

Ishishini laseChengyuan yinkampani ekhethekileyo ekuboneleleni ngezixhobo zemveliso ze-SMT kunye nePCBA.Ikubonelela ngesona sisombululo sifanelekileyo kuwe.Ineminyaka emininzi yokuvelisa kunye namava ophando.Iingcali zobuchwephesha zibonelela ngesikhokelo sokufakela kunye nenkonzo emva kokuthengisa kwindlu ngendlu, ukuze ungabi naxhala.

Ixesha lokuposa: Mar-06-2023