I-Reflow soldering linyathelo elibalulekileyo kwinkqubo ye-SMT.Iprofayili yeqondo lokushisa elihambelana nokuhamba kwakhona yiparameter ebalulekileyo yokulawula ukuqinisekisa ukudibanisa okufanelekileyo kweengxenye.Iiparameters zamacandelo athile ziya kuchaphazela ngqo iprofayili yeqondo lokushisa elikhethiweyo kweso sinyathelo kwinkqubo.

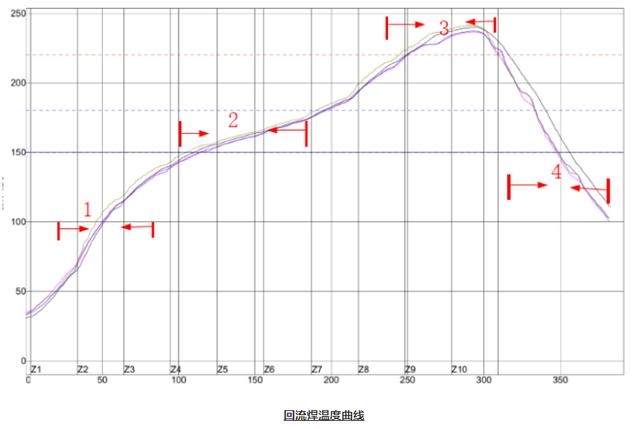

Kwi-conveyor ye-track-track, iibhodi ezinamalungu asanda kubekwa zidlula kwiindawo ezishushu kunye nezibandayo ze-oven yokuphinda iqhume.La manyathelo enzelwe ukulawula ngokuchanekileyo ukunyibilika kunye nokupholisa i-solder ukuzalisa amajoyina e-solder.Olona tshintsho lobushushu luphambili olunxulunyaniswa neprofayili yokuphinda luqukunjelwe lunokwahlulwa lube ngamanqanaba/imimandla emine (edweliswe ngezantsi kwaye iboniswe apha emva koko):

1. Zifudumeze

2. Ukufudumeza rhoqo

3. Ubushushu obuphezulu

4. Ukupholisa

1. Indawo yokufudumala

Injongo yendawo yokutshisa i-preheat ku-volatilize i-solvents ephantsi yokunyibilika kwi-solder paste.Amacandelo aphambili e-flux kwi-solder paste ibandakanya i-resins, i-activators, i-viscosity modifiers kunye ne-solvents.Indima ye-solvent ngokuyinhloko njengomphathi we-resin, kunye nomsebenzi owongezelelweyo wokuqinisekisa ukugcinwa okwaneleyo kwe-solder paste.Indawo yokufudumeza kufuneka iguqule i-solvent, kodwa iqondo lokushisa elinyukayo kufuneka lilawulwe.Amazinga okufudumeza okugqithisileyo anokugxininisa i-thermal icandelo, elingonakalisa icandelo okanye ukunciphisa ukusebenza kwalo / ubomi.Enye impembelelo yecala eliphezulu kakhulu lokufudumeza kukuba i-solder paste ingawa kwaye ibangele imijikelezo emfutshane.Oku kuyinyani ngokukodwa kwiipasti ze-solder ezinomxholo ophezulu we-flux.

2. Ummandla wobushushu rhoqo

Ukusetwa kommandla wobushushu obungaguqukiyo kulawulwa ikakhulu ngaphakathi kweeparamitha zomboneleli we-solder paste kunye nomthamo wobushushu wePCB.Eli nqanaba linemisebenzi emibini.Eyokuqala kukufumana ubushushu obufanayo kuyo yonke ibhodi yePCB.Oku kunceda ukunciphisa imiphumo yoxinzelelo lwe-thermal kwindawo yokubuyisela kwakhona kunye nokunciphisa ezinye iziphene ze-soldering ezifana nokuphakanyiswa kwecandelo elikhulu levolumu.Enye impembelelo ebalulekileyo yeli nqanaba kukuba i-flux kwi-solder paste iqala ukusabela ngokukrakra, ukwandisa ukumanzi (kunye namandla angaphezulu) kwi-weldment surface.Oku kuqinisekisa ukuba i-solder etyhidiweyo imanzisa umphezulu we-solder kakuhle.Ngenxa yokubaluleka kwale nxalenye yenkqubo, ixesha lokucwina kunye nokushisa kufuneka kulawulwe kakuhle ukuze kuqinisekiswe ukuba i-flux ihlambulule ngokupheleleyo i-soldering surfaces kwaye i-flux ayigqithwanga ngokupheleleyo ngaphambi kokuba ifike kwi-reflow soldering process.Kuyimfuneko ukugcina i-flux ngexesha lesigaba sokubuyisela njengoko iququzelela inkqubo yokumanzisa i-solder kwaye inqande ukuphinda kufakwe i-oxidation yendawo ethengisiweyo.

3. Indawo yobushushu obuphezulu:

Ummandla weqondo lokushisa eliphezulu kulapho ukunyibilika okupheleleyo kunye nokumanzisa ukuphendula kwenzeka apho i-intermetallic layer iqala ukwenza.Emva kokufikelela kwiqondo lokushisa eliphezulu (ngaphezulu kwe-217 ° C), ukushisa kuqala ukuhla kwaye kuwela ngaphantsi komgca wokubuyela, emva koko i-solder iqinisa.Le nxalenye yenkqubo nayo ifuna ukulawulwa ngononophelo ukwenzela ukuba irempu yobushushu inyuke nasezantsi ingayibekeli inxalenye yokothuka kwe-thermal.Ubushushu obuphezulu kwindawo yokubuyisela kwakhona buchongwa ngokuxhathisa ubushushu bezinto ezinobushushu kwi-PCB.Ixesha elikwindawo yobushushu obuphezulu kufuneka libe lifutshane kangangoko ukuqinisekisa ukuba amacandelo adityaniswe kakuhle, kodwa alibanga lide kangangokuba umaleko we-intermetallic ube mkhulu.Ixesha elifanelekileyo kulo mmandla lidla ngokuba yi-30-60 imizuzwana.

4. Indawo yokupholisa:

Njengenxalenye yenkqubo yokuthengiswa kwe-reflow iyonke, ukubaluleka kweendawo zokupholisa kuhlala kungahoywa.Inkqubo efanelekileyo yokupholisa nayo idlala indima ephambili kwisiphumo sokugqibela se-weld.Ukudibanisa okuhle kwe-solder kufuneka kukhanye kwaye kube flat.Ukuba isiphumo sokupholisa asilungile, iingxaki ezininzi ziya kwenzeka, ezifana nokuphakama kwecandelo, i-solder joints, iindawo ezidityanisiweyo ezingalinganiyo kunye nokujiya kwe-intermetallic compound layer.Ke ngoko, i-reflow soldering kufuneka ibonelele ngeprofayili elungileyo yokupholisa, ingakhawulezi kakhulu okanye icothe kakhulu.Ucotha kakhulu kwaye ufumana eminye yemiba yokupholisa engalunganga ekhankanywe ngasentla.Ukupholisa ngokukhawuleza kunokubangela ukutshatyalaliswa kwe-thermal kumalungu.

Ngokubanzi, ukubaluleka kwenyathelo lokubuyela kwakhona kwe-SMT alinakujongelwa phantsi.Inkqubo kufuneka ilawulwe kakuhle ngeziphumo ezihle.

Ixesha lokuposa: May-30-2023